Lilemong tsa morao tjena, ka matsete a maholo a lits'ebeletso tsa motheo le tsoelo-pele e potlakileng ea indasteri Chaena, tlhahiso le tšebeliso ea indasteri eohle ea litlaleho tsa aluminium li ntse li hōla ka potlako, 'me Chaena e fetohile setsi se seholo ka ho fetisisa lefatšeng sa tlhahiso ea aluminium le mmaraka oa bareki. .Ka mor'a lilemo tse ka bang 10 tsa khōlo e potlakileng, indasteri ea profil ea aluminium ea Chaena e kene sethaleng se secha sa nts'etsopele, 'me e bontšitse mekhoa e mengata e mecha ea tsoelo-pele.

Ho feta moo, ka tsoelo-pele e potlakileng ea kaho, lipalangoang, likoloi le matla a letsatsi le liindasteri tsa LED, litlhoko tsa ho nepahala ho phahameng le ts'ebetso e phahameng ea lihlahisoa tsa aluminium alloy extrusion li ntse li eketseha letsatsi le letsatsi, 'me sebopeho sa karolo ea profil se rarahane ebile se fapane,' me moo. ho na le mefokolo e mengata moralong oa liforomo tse tloaelehileng le tse tloaelehileng.Ka hona, ho fumana lintlha tsa boleng bo holimo, re tlameha ho lula re ithuta le ho ipokellela tlhahisong le bophelong, le ho lula re fetola le ho nchafatsa.

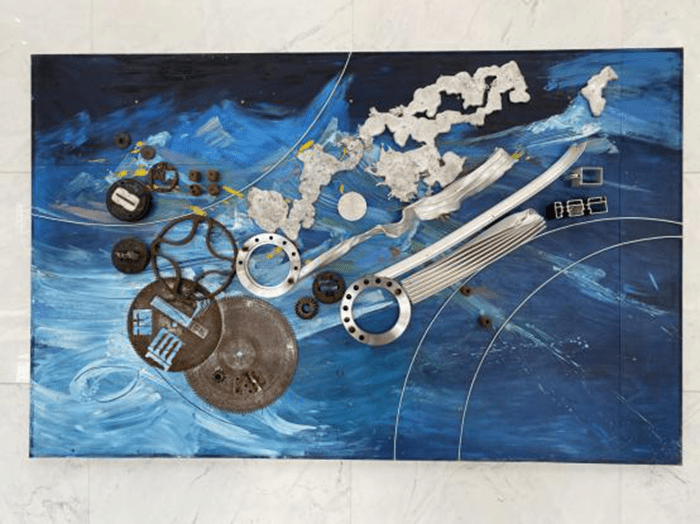

Moqapi oa hlobo ke sehokelo sa bohlokoa.Ka hona, hoa hlokahala ho sekaseka moralo oa hlobo oa profil e fetisitsoeng ka mokhoa o hlophisehileng le ho rarolla mathata mohato ka mohato ka tloaelo ea tlhahiso.

Lintlha tse 6 tsa bohlokoa tsa moralo oa hlobo oa profil ea aluminium

1. Tlhahlobo ea boholo ba likarolo tsa aluminium extruded

Boholo le ho kheloha ha likarolo tse extruded li khethoa ke lefu, thepa ea extrusion le lintlha tse ling tse amehang tsa ts'ebetso. Har'a tsona, phetoho ea boholo ba hlobo e na le tšusumetso e kholo, 'me mabaka a amang phetoho ea boholo ba hlobo ke: the elastic deformation. ea hlobo, ho phahama ha mocheso oa hlobo, thepa ea hlobo le ho nepahala ha ho etsoa ha hlobo le ho apara ha hlobo.

(1) khetho ea tonnage ea aluminium extruder

Karolelano ea extrusion ke palo ea lipalo tsa bothata ba hlobo ho fihlela extrusion.Ka kakaretso, ho sebetsa karo-karolelano ea extrusion lipakeng tsa 10-150. The extrusion ratio e ka tlase ho 10, thepa ea mochini ea sehlahisoa e tlase; Ho fapana le hoo, extrusion ratio e phahame haholo, sehlahisoa se sekametse ho roughness kapa Angle. kheloha le liphoso tse ling.Solid Profiles hangata kgothaletswa extrusion ratio in about 30, hollow profiles in about 45.

(2) Boikemisetso ba litekanyo tsa ka ntle

Litekanyo tse ka ntle tsa "extrusion die" li bua ka bophara le botenya ba "die.The dimensions" tsa hlobo li khethoa ke boholo, boima le matla a karolo ea profil.

2. Palo e utloahalang ea extrusion die size

Ha ho baloa boholo ba lesoba, ho nahanela ka sehloohong ka extrusion ea motsoako oa aluminium motsoako oa lik'hemik'hale, sebopeho sa sehlahisoa, boholo ba lebitso le mamello, mocheso oa extrusion, le lintho tse entsoeng ka hlobo 'me li petelitsoe tlas'a motsoako oa mocheso, katoloso ea coefficient ea linear ea sehlahisoa. litšobotsi tsa geometry ea cross section, le liphetoho tsa eona nakong ea ho otlolla, lintlha tse kang boholo ba khatello ea extrusion le deformation rekere ea die.

Bakeng sa litlaleho tse nang le phapang e kholo ea marako, likarolo tse tšesaane tse nang le marako le libaka tse bohale tse thata ho theha li lokela ho eketsoa ka boholo ka mokhoa o nepahetseng.

Bakeng sa masoba a li-file tsa profiles tsa lebota tse bataletseng le tse tšesaane le li-profiles tsa lebota tse nang le bophara bo boholo ho isa ho botenya, boholo ba literempe li ka etsoa ho latela lintlha tse akaretsang, le boholo ba botenya ba webo, ho kenyelletsa lintlha tse thathamisitsoeng ho formula, hape lokela ho nahana ka deformation rekere, deformation polasetiki, ho kobeha ka kakaretso, sebaka ho tloha bohareng ba moqomo extrusion le lintlha tse ling.Ho phaella moo, lebelo extrusion, traction sesebediswa le joalo-joalo hape ba le phello e itseng ka boholo ba lesoba shoa. .

3. Phetoho e utloahalang ea lebelo la ho phalla ha tšepe

Seo ho thoeng ke phetoho e utloahalang ke ho etsa bonnete ba hore karolo e 'ngoe le e' ngoe e karolong ea sefapano sa sehlahisoa e lokela ho phalla ka ntle ho lesoba la die ka lebelo le le leng tlas'a boemo bo loketseng.

Ho ea kamoo ho ka khonehang ho sebelisa tlhophiso ea porous symmetrical, ho latela sebopeho sa profil, phapang ea botenya ba lebota la karolo e 'ngoe le e' ngoe le phapang ea selikalikoe le sebaka ho tloha bohareng ba silinda ea extrusion, moralo oa lebanta la bolelele bo fapaneng. .Ka kakaretso, karolo e fokolang ea lerako la lerako, e kholoanyane ea selika-likoe, sebopeho se rarahaneng haholoanyane, ho tloha bohareng ba cylinder ea extrusion, ho khutsufala ha lebanta la boholo mona le lokela ho ba teng.

Ha lebanta la sizing le ntse le le thata ho laola sekhahla sa phallo, sebopeho se rarahane ka ho khetheha, botenya ba lerako bo tšesaane haholo, hole le bohareng ba karolo e ka sebelisoa ho ntšetsa pele phallo ea Angle kapa khoune ea tataiso ho potlakisa phallo ea tšepe. Ho fapana le hoo, bakeng sa likarolo tseo tse nang le marako a teteaneng haholo kapa tse haufi haholo le bohareng ba moqomo oa extrusion, ho lokela ho sebelisoa Angle e thibelang ho tlatsetsa tšitiso ho fokotsa sekhahla sa phallo mona. Ho phaella moo, sekoti se leka-lekaneng, mokhoa oa ho sebetsa. tumello, kapa ho sebelisoa ha kamore e ka pele shoa, motataisi shoa, fetola palo, boholo, sebopeho le boemo ba lesoba le petsoha ho lokisa sekhahla phallo tšepe.

4. Netefatsa matla a hlobo a lekaneng

Hobane boemo ba ho sebetsa ba lefu bo bobe haholo nakong ea extrusion, matla a lefu ke bothata ba bohlokoa haholo ho moralo oa lefu.Ho phaella ho tlhophiso e utloahalang ea sebaka sa likoti tsa lefu, khetho ea lisebelisoa tse loketseng tsa lefu, moralo oa lefu le utloahalang. sebopeho le sebopeho, lipalo tse nepahetseng tsa khatello ea extrusion le ho hlahloba matla a lumellehang a karolo ka 'ngoe e kotsi le eona ke ea bohlokoa haholo.

Hona joale, ho na le mekhoa e mengata ea ho bala matla a extrusion, empa mokhoa o fetotsoeng oa Beerling o ntse o e-na le boleng ba boenjiniere.Mokhoa oa tharollo ea moeli o ka holimo oa khatello ea extrusion e boetse e na le boleng bo botle ba kopo, 'me ho bonolo ho bala khatello ea extrusion ka ho sebelisa mokhoa oa empirical coefficient. .

Ha e le ho hlahloba matla a hlobo, ho lokela ho etsoa ho ea ka mofuta oa sehlahisoa, sebopeho sa hlobo, joalo-joalo; e lokela ho hlahlobjoa, 'me matla a thata a leleme le nale a boetse a lokela ho nkoa.

E 'ngoe ea mathata a mantlha a ho hlahloba matla ke ho khetha mokhoa o nepahetseng oa khopolo ea matla le khatello ea maikutlo e nepahetseng haholoanyane. Lilemong tsa morao tjena, ho ka sebelisoa mokhoa oa finite element ho hlahloba matla le ho hlahloba matla a lefu le rarahaneng haholo.

5. Boholo ba bophara ba lebanta le sebetsang

Ho rarahane haholo ho fumana sebaka sa ho sebetsa sa mokelikeli oa motsoako o arohaneng ho feta oa halofo ea shoa, eseng feela phapang ea botenya ea lebota la profil le sebaka se pakeng tsa bohareng, empa hape le ho sireletsa lesoba la lefu ka borokho bo arohaneng. e tlameha ho nkoa.Ka lesoba la die tlas'a borokho bo arohaneng, lebanta la mosebetsi le tlameha ho fokotsoa ka lebaka la bothata ba ho phalla ha tšepe.

Ha ho etsoa qeto ea sebaka mosebetsi, ea pele ho fumana ho fetisisa tšesaane lerako botenya ka triage borokho profil ka tšepe phallo khanyetso ea kholo ka ho fetisisa sebakeng seo, mosebetsi bonyane habeli e le botenya lerako, lerako botenya botenya kapa tšepe ke ho le bonolo ho finyella, sebetsa. ha ho nahanoa ka botenya, hangata ho latela kamano e itseng, hammoho le ho phalla ha bonolo ha se ntlafalitsoeng.

6. Sebopeho sa thipa e se nang letho ea lesoba

The hole hole cutter ke cantilever support structure at outlet of the die hole working lebanta.Profile lebota botenya T ≥2.0mm, e ka sebelisoa ho sebetsa bonolo otlolohileng sehang sehang sebopeho;Ha t<2mm, kapa ka cantilever, ka sebelisa thipa e se nang letho e oblique.

Tse peli.Mathata a tloaelehileng ho moralo oa hlobo

1. Karolo ea kamore ea bobeli ea welding

Extrusion die e phetha karolo ea bohlokoa ho extrusion ea profiles aluminium, e amang ka ho toba boleng ba lihlahisoa extruded.Leha ho le joalo, ka tlhahiso ea sebele, moralo oa extrusion shoa e itšetlehile haholo ka phihlelo ea moqapi, le boleng ba lefu. moralo o thata ho netefatsa, ka hona hoa hlokahala ho leka le ho lokisa lefu ka makhetlo a mangata.

Ho ea ka mefokolo ea moralo oa lefu, moralo o nepahetseng oa moralo oa ho beha likamore tse peli tsa ho tjheseletsa mokatong o ka tlase o ile oa beoa pele, o neng o etsa mefokolo ea ho fepa ka mokhoa o sa phetheheng oa ho sebetsa, ho qoba liphoso tsa ho bula, ho koala le phapang ea sebopeho pele ka mor'a ho lokolloa ha lintho tse bakoang ke ho fepa ho sa lekaneng, 'me ka katleho ho rarolle bothata ba ho ajoa ha lebelo le sa tsitsang ho moralo.Ka lebaka leo, morerong oa ho ntlafatsa, mocheso le khatello ea maikutlo karolong ea profil li tšoana haholo,' me thepa e ntlafatsoa haholo.

2. Karolo ea phalliso ea bobeli

Moqaping oa "extrusion die", "diversion" ea bobeli e sebelisoa bakeng sa lintlha tse tiileng tse nang le phapang e kholo ea lerako. Mohlala: Moqapi oa pele oa hlobo o entsoe ka hlobo e tloaelehileng le pad ea die.Ha e ntle ka lekhetlo la pele.The Angle e nyenyane, 'me karolo e tšesaane e nang le marako ke ea ultra-thin and ultra-small.Ho lokisoa ha hlobo ha hoa lekana le haeba karolo e tšesaane e nang le marako e atolosoa' me lebanta le sebetsang le theoleloa.

E le ho rarolla bothata ba ho ajoa ha lebelo le sa tsitsang moralong oa pele oa hlobo, moralo oa poleiti ea tataiso o ile oa amoheloa ka lekhetlo la bobeli, 'me moralo o nepahetseng oa ho beha maemo a mabeli a tataiso ka hlobo o ile oa behoa pele.

Ho bua ka ho toba, lerako le tšesaane le lebisitsoe ka ho toba, karolo e teteaneng ea lerako e hasoa ka likhato tse 30 ka bophara ba sekoti, 'me boholo ba lesoba la karolo e teteaneng ea lerako le eketseha ka boholo,' me Angle ea 90 ea lesoba la lefu ke e koetsoe pele le ho buloa ho likhato tse 91, 'me lebanta la ho sebetsa la sizing le lona le fetotsoe ka nepo.

Nako ea poso: Mar-18-2021